Samsung announces plans to build new $17 billion chip factory in Texas

11/25/2021 / By Cassie B.

Samsung has announced plans to build a $17 billion semiconductor factory near Austin, Texas, in the next three years in what is said to be the most significant foreign direct investment in the state’s history. The new factory is part of an effort by the South Korean tech giant to raise its manufacturing capacity and help stem a worldwide chip shortage.

The 5-million-square-meter facility will be built in Taylor and will be used for producing advanced logic semiconductors for phones, computers, 5G and artificial intelligence.

Construction on the factory is scheduled to get underway in the first half of 2022, with the company aiming to have it operational by the end of 2024. It is expected to create 1,800 jobs. The $17 billion expected investment will be the biggest investment the company has ever made in the United States and includes buildings, machinery, equipment and property improvements.

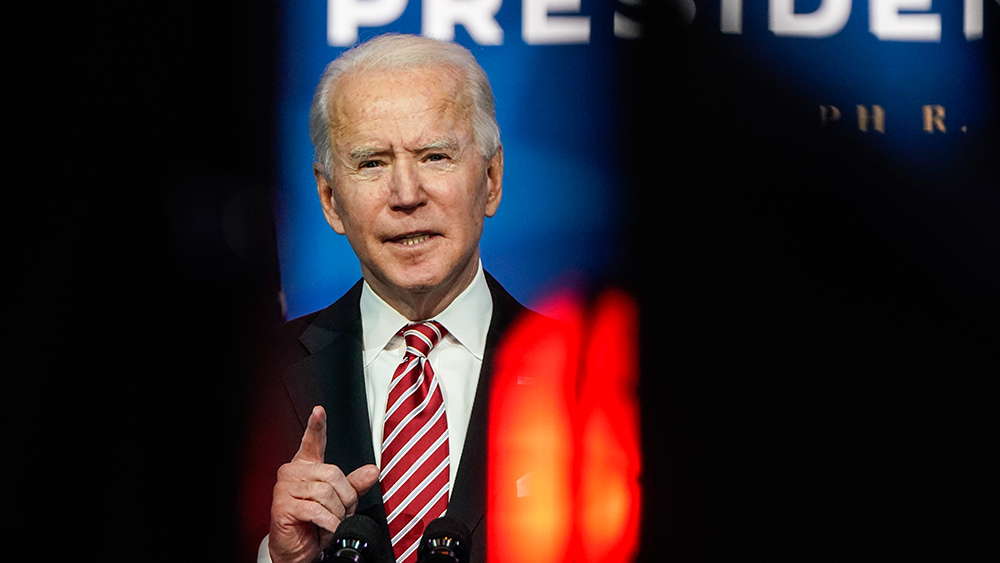

Earlier this year, President Joe Biden announced that domestic semiconductor manufacturing would be a priority for his administration as they aim to fix the ongoing chip shortages and address concerns raised by some lawmakers that outsourcing chipmaking could make America more vulnerable to disruptions in the supply chain. The U.S. share of the global chip manufacturing market has dropped from 37 percent in 1990 to 12 percent percent today, according to the trade group the Semiconductor Industry Association.

There is also a geopolitical risk as many American companies depend on chips produced in Taiwan, which China claims is its own territory.

In a statement praising the announcement by Samsung, U.S. Commerce Secretary Gina Raimondo said: “Increasing domestic production of semiconductor chips is critical for our national and economic security.”

Right now, most of the world’s chips are being made in Asia, particularly in South Korea and Taiwan. Recently, the U.S. and Europe have expressed a desire to start making more of their own chips. Low supplies of semiconductors thanks to COVID shutdowns have been impacting the production of electronic devices and new vehicles for more than a year. Even after the current shortages subside, the demand for chips is only expected to rise as increasing numbers of everyday products use them.

Great news for Texas

Texas Governor Greg Abbott said that the factory would provide lots of opportunities for people living in Central Texas. He said: “Samsung’s new semiconductor manufacturing facility in Taylor will bring countless opportunities for hardworking Central Texans and their families and will play a major role in our state’s continued exceptionalism in the semiconductor industry. I look forward to expanding our partnership to keep the Lone Star State a leader in advanced technology and a dynamic economic powerhouse.”

It is believed that the company chose Taylor because they already have an ecosystem of suppliers and partners in Texas thanks to their existing factory in Austin. Moreover, the weather and geological stability of Texas makes it well-suited to this type of facility.

Taylor’s Mayor, Brandt Rydell, was thrilled about Samsung’s decision, calling it the “single most significant and consequential development for the local economy since the International & Great Northern Railroad laid tracks here in the 1870s.”

According to the Wall Street Journal, Taylor officials incentivized Samsung by offering them property tax breaks of more than 90 percent during the first ten years, with write-offs declining gradually in the coming decades.

This spring, one of Samsung’s main rivals in the semiconductor manufacturing sphere, Intel, announced that it would be investing $20 billion in the construction of two new chip plants in Arizona, while another competitor, TSMC, is also building a new factory in Arizona.

Sources for this article include:

Tagged Under: Big Tech, Bubble, chips, economy, factory, product, risk, Samsung, semiconductor, semiconductors, supply, tech giants, technocrats, Texas

RECENT NEWS & ARTICLES

COPYRIGHT © 2017 RISK NEWS